VCS

VERICUT Composites Simulation

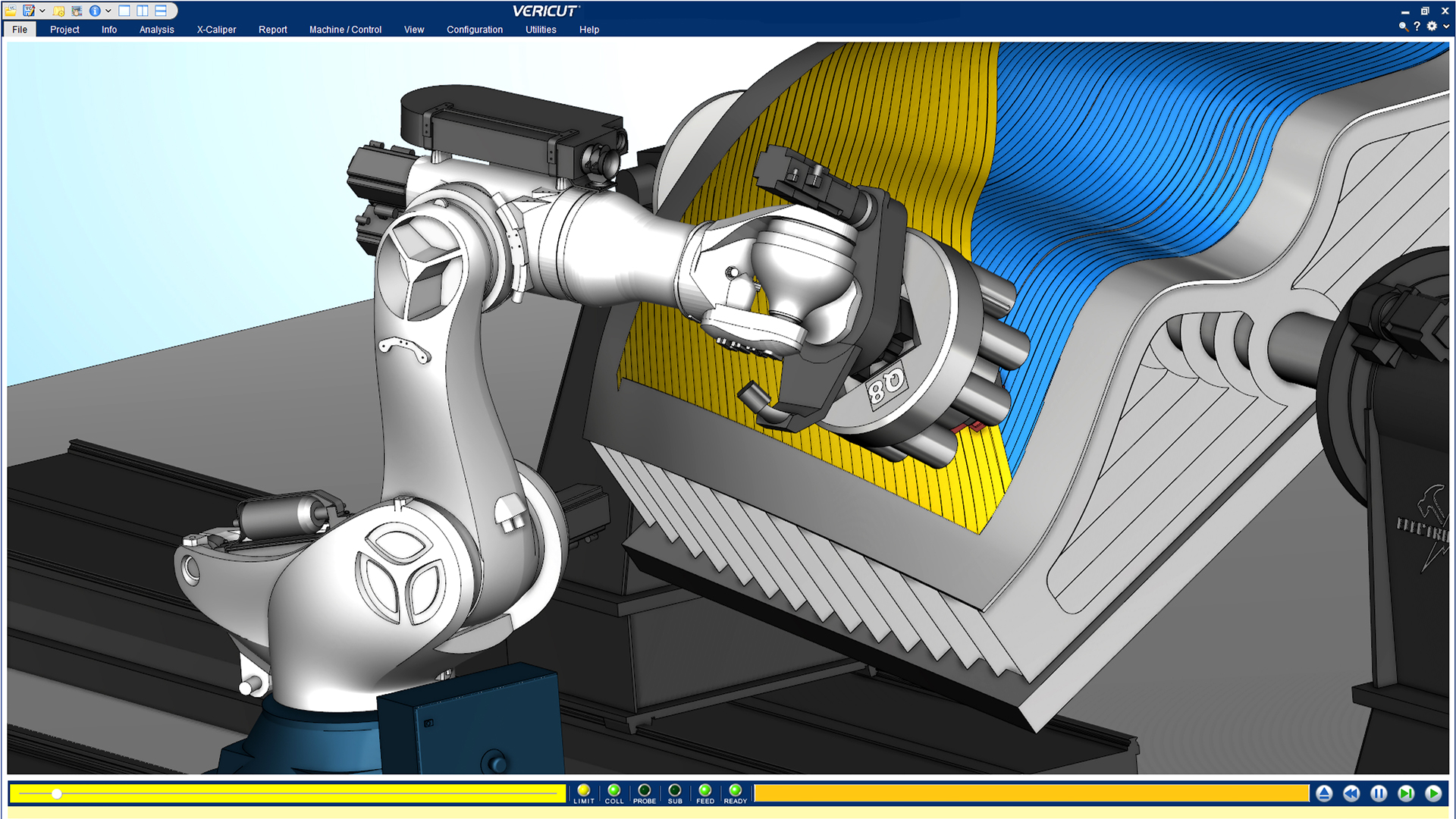

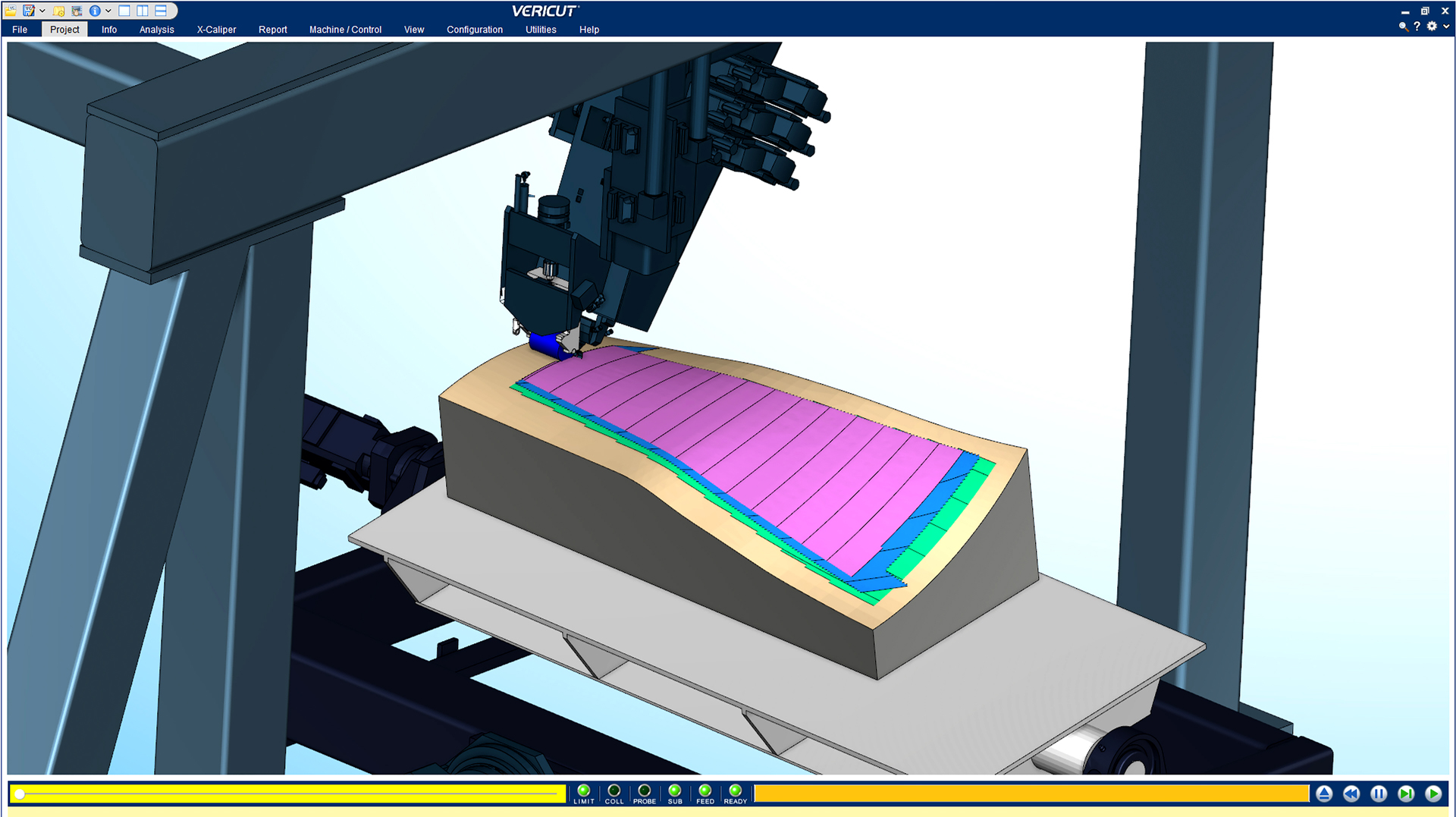

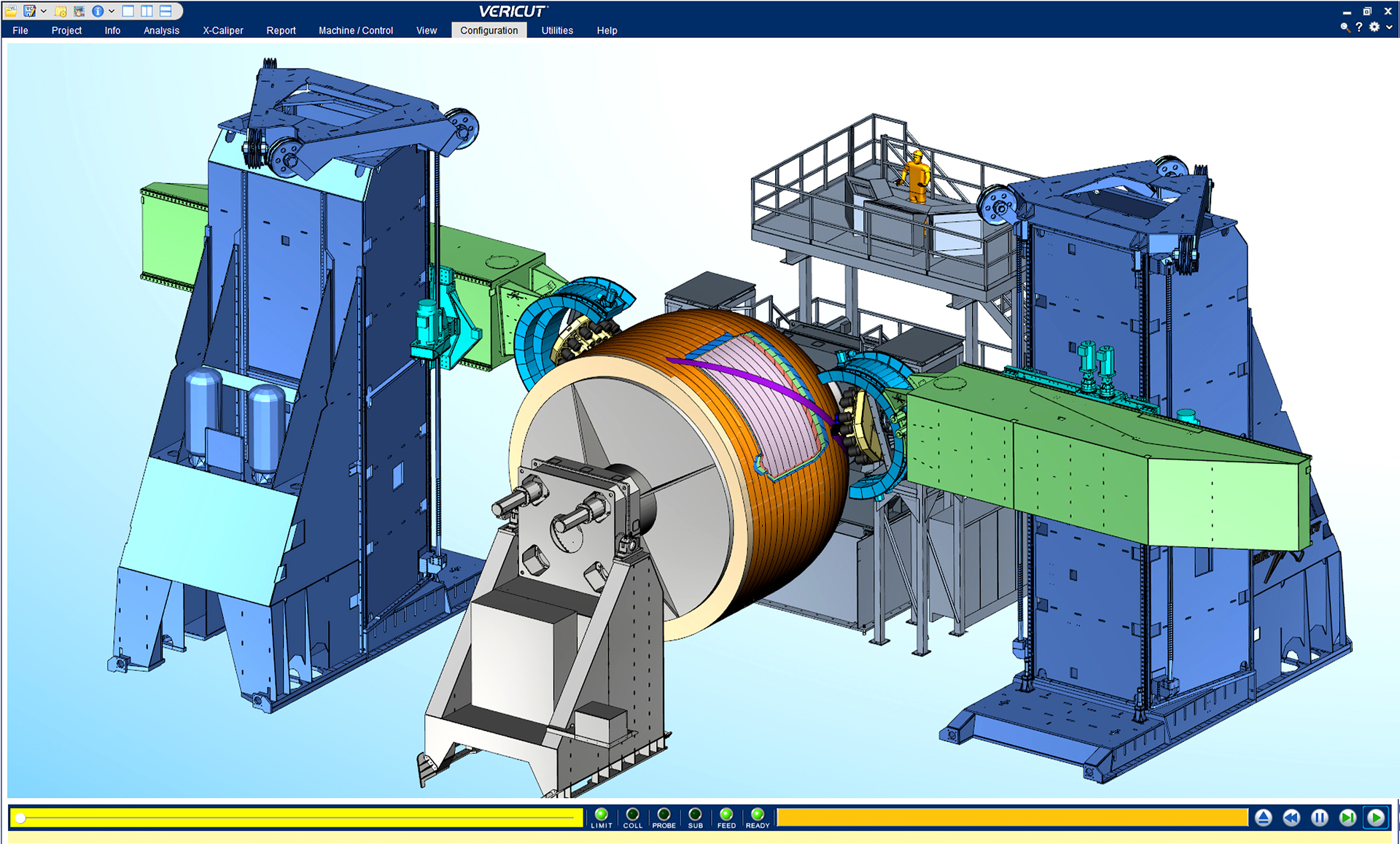

VERICUT Composite Simulation (VCS) is a simulated work environment for automated composites manufacturing. Through CAD models and NC programs, VCS simulates the sequence of NC programs on a virtual machine, including head changes, probing, knife cutting, and more. Material is applied to the layup form via NC program instructions in a virtual CNC simulation environment. The simulated material applied to the form can be measured and inspected for stack thickness, ply offset, ply angle, and other manufacturing priorities to ensure the NC program follows manufacturing standards and requirements. A report showing simulation results and statistical information can be automatically created.

Fiber Placement Machine Simulation details:

• Based on industry leading VERICUT Software

• User-configurable machine kinematics and control emulation models for any machine and control

• Reads and simulates ISO (G-Code) NC program file

VERICUT Composite Machine Simulation & Analysis Features:

Reads CAD geometry of the layup form

• Used for collision detection and material application

Uses VERICUT virtual machine and control emulation to simulate the layup machinery

• Can be configured for virtually any CNC syntax and machine kinematics configuration

Reads the NC program and simulates the layup process based on NC program commands

• Validate the actual NC program that will run on the layup equipment

• Add material to the form based on NC program commands

• Material added in discreet layers/sequences, constructing the workpiece exactly like the physical process

Checks the process for compaction roller/form conformance and direction

• Verify roller orientation to path

• Verify path correctness to the form and previously applied sequences/layers of material

• Check roller conformance and compaction axis travel for bridging or excessive compaction

Added material is measurable and can be inspected for manufacturing requirements

• Measure overlap and gap areas

• Interrogate simulated material for thickness

• Detect steering radius violations

• Verify ply stagger

Visit the Electroimpact Showroom

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan